#mini PLC (Programmable Logic Controller)

Explore tagged Tumblr posts

Text

ARM Industrial Edge Gateway Combined with SCADAbr Open source SCADA for Water Treatment Solutions

Case Details

Pairing an ARM-based embedded industrial PC with SCADAbr software offers an efficient, flexible, and cost-effective solution for water treatment systems. Below is a detailed explanation of how to integrate these technologies for water treatment applications.

1. Features and Advantages of ARM Industrial Edge Gateway

ARM Industrial Edge Gateway are well-suited for water treatment due to the following characteristics:

Low Power Consumption and High Performance: ARM processors are known for their energy efficiency, ideal for continuous operation in water treatment systems, while providing sufficient computing power for real-time data processing.

Rich Interface Support: They offer various industrial interfaces (e.g., RS232, RS485, CAN, Ethernet, Wi-Fi, 4G/5G modules), facilitating connections to sensors, PLCs (Programmable Logic Controllers), RTUs (Remote Terminal Units), and other field devices.

Compact Design and High Reliability: ARM Industrial Edge Gateway are small, suitable for embedded installations, and typically feature wide-temperature operation, dust resistance, and shock resistance, making them ideal for harsh water treatment environments (e.g., humid or high-temperature conditions).

Open-Source Support: ARM architecture supports open-source operating systems like Linux, enabling easy deployment of SCADAbr and allowing customization based on specific needs.

2. Role of SCADAbr in Water Treatment

SCADAbr, an open-source SCADA (Supervisory Control and Data Acquisition) software, provides the following functionalities for water treatment:

Data Acquisition: Collects real-time data from sensors (e.g., pH meters, turbidity sensors, flow meters) and actuators (e.g., pumps, valves) via protocols like Modbus RTU/TCP or OPC UA.

Real-Time Monitoring: Displays water quality parameters (e.g., pH, dissolved oxygen, turbidity), equipment status (e.g., pump on/off), and process flows (e.g., filtration, dosing) through a web-based interface.

Alarm Management: Triggers alarms for out-of-spec water quality parameters (e.g., high turbidity) or equipment failures, notifying operators via the interface, email, or SMS.

Historical Data Logging: Stores water quality and equipment operation data, supporting trend analysis and report generation for process optimization and regulatory compliance.

Remote Control: Allows operators to adjust equipment settings (e.g., pump speed, valve position) remotely via a browser, improving response times.

3. Integration of ARM Industrial Edge Gateway and SCADAbr

Combining an ARM Industrial Edge Gateway with SCADAbr creates a lightweight, modular water treatment monitoring system:

Hardware Platform: An ARM Industrial Edge Gateway (e.g., based on Rockchips RK3568 BL410 series or NXP i.MX8 mini BL360 series) runs a Linux system with SCADAbr installed. Its multiple interfaces ensure stable and real-time data acquisition from field devices.

Software Configuration:

Configure communication drivers (e.g., Modbus, DNP3) in SCADAbr to interface with PLCs or RTUs in the water treatment system.

Use SCADAbr’s configuration tool to design monitoring interfaces, displaying process flow diagrams (e.g., intake, sedimentation, filtration, disinfection).

Set up data points (tags) mapped to the physical addresses of sensors and actuators for data collection and control.

Communication Architecture:

Field Layer: Sensors and actuators connect to the ARM Industrial Edge Gateway via RS485 or Ethernet.

Control Layer: The ARM IPC runs SCADAbr, processing data and executing control logic.

Management Layer: Operators access the SCADAbr interface via a web browser (on PCs, tablets, or smartphones) to monitor and control the water treatment system.

4. Specific Applications in Water Treatment

In water treatment scenarios, the ARM Industrial Edge Gateway and SCADAbr combination can achieve the following:

Drinking Water Treatment:

Monitor raw water quality (turbidity, pH, residual chlorine) and control dosing pumps (e.g., for coagulants or disinfectants).

Track filter pressure and flow rates, triggering backwashing operations.

Generate water quality reports to ensure compliance with standards (e.g., WHO or national regulations).

Wastewater Treatment:

Monitor dissolved oxygen and sludge concentration in aeration tanks, optimizing aeration for energy savings.

Control lift pumps and mixers to manage wastewater treatment stages (pre-treatment, biological treatment, sedimentation).

Detect effluent parameters like COD or BOD, triggering alarms to prevent non-compliant discharge.

Industrial Wastewater Treatment:

Monitor heavy metal content or pH to ensure compliance with environmental regulations.

Automatically adjust neutralizing agent dosing to minimize chemical waste.

Integrate with MES (Manufacturing Execution Systems) to log treatment data for audits.

5. Advantages and Challenges

Advantages:

Cost-Effective: ARM Industrial Edge Gateway are affordable, and SCADAbr is open-source and free, making the solution significantly cheaper than commercial SCADA systems.

Flexibility: The modular design of ARM Industrial Edge Gateway and the open-source nature of SCADAbr allow for customized development, suitable for water treatment projects of varying scales.

Remote Access: SCADAbr’s web-based interface supports remote monitoring, reducing the need for on-site personnel.

Scalability: Easily accommodates additional sensors or devices, supporting system upgrades or expansions.

Challenges:

Performance Limitations: ARM Industrial Edge Gateway may have lower computing power compared to high-end industrial PCs, potentially limiting performance in large-scale data processing.

Technical Expertise: Configuring SCADAbr and deploying ARM Industrial Edge Gateway requires some technical knowledge, which may pose a challenge for beginners.

Security: Open-source systems may have vulnerabilities, necessitating robust network security measures (e.g., firewalls, encrypted communication) to prevent unauthorized access.

6. Implementation Recommendations

Hardware Selection: Choose an ARM Industrial Edge Gateway ARMxy series with wide-temperature support and rich I/O interfaces to match water treatment site conditions.

Software Optimization:

Run SCADAbr on a lightweight Linux distribution (e.g., Ubuntu Server, Debian) to minimize resource usage.

Regularly update SCADAbr to address vulnerabilities and ensure system stability.

Network Architecture: Deploy industrial Ethernet or 4G/5G networks to ensure reliable and real-time data transmission.

Security Measures:

Implement user authentication and access control to restrict SCADAbr access.

Use VPNs or TLS to encrypt remote communications and prevent data breaches.

Testing and Validation: Conduct simulation tests before deployment to verify accurate sensor data collection and reliable control logic.

7. Case Study Reference

Based on available information (e.g., case studies on open-source SCADA with ARM embedded systems), similar solutions have been successfully applied in small-scale water treatment plants. For example, a wastewater treatment facility used an ARM Industrial Edge Gateway running SCADAbr to monitor multiple submersible pumps and aeration devices via Modbus, enabling remote water quality management and equipment maintenance, significantly reducing operational costs.

Conclusion

The combination of an ARM Industrial Edge Gateway and SCADAbr provides an economical and efficient solution for water treatment, particularly for small to medium-sized projects. Its low power consumption, flexibility, and open-source nature excel in data acquisition, real-time monitoring, and remote control. With proper hardware selection, software configuration, and security measures, a stable and reliable water treatment monitoring system can be established.

0 notes

Text

PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, a PLC Training Institute In Pune. Our institution leads the way, offering specialized courses and advanced centers dedicated to teaching PLCs. Whether you are starting your career or trying to hone your skills, our bespoke programs meet a variety of needs.

Firstly, Perfecto Robotics Institute offers hands-on training led by industry experts. Students actively participate in practical exercises. Students develop a deeper understanding of PLC systems by doing p; practical exercises. Additionally, our instructors emphasize real-world applications, ensuring graduates are well-prepared for technological challenges.

What is PLC?

It stands for Programmable Logic Controller. PLC is the ruggedized computer used in industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

Different types of PLC

Mini PLCs

Modular PLCs

Fixed PLCs

Micro PLCs

Nano PLCs

Safety PLCs

Types of PLC Output:

Analog Output

Relay Output

Triac Output

Transistor Output

PLC features:

Robustness

Flexibility

Modularity

High-speed Operation

Reliable I/O Handling

Networking Capabilities

Programming Languages

Diagnostic and Troubleshooting Tools

Data Handling and Storage

Scalability and Upgradability

Overall, these features make Programmable Logic Controllers indispensable tools in industrial automation.

In conclusion, Perfecto Robotics Institute is the best PLC Training Institute In Pune. We stand out for its practical approach, advanced facilities, and industry-related learning. Contact us to start a successful career in industrial automation.

Explore our courses today and take the first steps to becoming a professional PLC professional.

Looking for top-quality PLC training in Pune? Our institute offers hands-on training in PLC programming Learn from experienced trainers, gain practical knowledge with real-time projects, and boost your career prospects with our comprehensive courses. We offer flexible batch timings, affordable fees, and placement assistance to help you succeed. Enroll now and become job-ready in automation!

0 notes

Text

PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, a PLC Training Institute In Pune. Our institution leads the way, offering specialized courses and advanced centers dedicated to teaching PLCs. Whether you are starting your career or trying to hone your skills, our bespoke programs meet a variety of needs.

Firstly, Perfecto Robotics Institute offers hands-on training led by industry experts. Students actively participate in practical exercises. Students develop a deeper understanding of PLC systems by doing p; practical exercises. Additionally, our instructors emphasize real-world applications, ensuring graduates are well-prepared for technological challenges.

What is PLC?

It stands for Programmable Logic Controller. PLC is the ruggedized computer used in industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

Different types of PLC

Mini PLCs

Modular PLCs

Fixed PLCs

Micro PLCs

Nano PLCs

Safety PLCs

Types of PLC Output:

Analog Output

Relay Output

Triac Output

Transistor Output

PLC features:

Robustness

Flexibility

Modularity

High-speed Operation

Reliable I/O Handling

Networking Capabilities

Programming Languages

Diagnostic and Troubleshooting Tools

Data Handling and Storage

Scalability and Upgradability

Overall, these features make Programmable Logic Controllers indispensable tools in industrial automation.

In conclusion, Perfecto Robotics Institute is the best PLC Training Institute In Pune. We stand out for its practical approach, advanced facilities, and industry-related learning. Contact us to start a successful career in industrial automation.

Explore our courses today and take the first steps to becoming a professional PLC professional.

Looking for top-quality PLC training in Pune? Our institute offers hands-on training in PLC programming Learn from experienced trainers, gain practical knowledge with real-time projects, and boost your career prospects with our comprehensive courses. We offer flexible batch timings, affordable fees, and placement assistance to help you succeed. Enroll now and become job-ready in automation!

0 notes

Text

Best Universal Filler in India

click here :- https://www.goodlifemachine.com/bakery-machines/universal-filler

In the dynamic landscape of the baking industry, precision and efficiency are paramount. Recognizing the unique needs of small bakeries, GOODLIFE TECHNOLOGIES PVT. LTD. takes pride in presenting the Best Universal Filler in India—a state-of-the-art mini depositor designed for various depositing applications.

1. Versatility Unleashed:

The Universal Filler is equipped with a comprehensive set of attachments, including a handgun, spot deposit attachment, and cream filling nozzles. This versatility empowers small bakeries to handle an extensive range of depositing tasks, offering flexibility in product creation.

2. Precision Through Technology:

Operating seamlessly through a servo motor and lube pump, this mini depositor ensures unparalleled precision. Controlled by a Programmable Logic Controller (PLC), the machine exemplifies cutting-edge technology, providing a level of accuracy crucial for successful bakery operations.

0 notes

Text

Exploring Emerging Technologies: Mini Projects in ECE

The emergence of new technologies in the field of electrical and computer engineering (ECE) presents a unique opportunity for students to explore cutting-edge concepts and create mini-projects to gain valuable experience. Mini projects in ECE are an excellent way for students to explore a new technology and gain hands-on experience with a technology before committing to a more complex project.

Mini projects can allow students to gain a deeper understanding of a technology, as they are able to explore and experiment with the technology in a more contained environment. By taking on mini projects in ECE, students can gain insight into the technology’s capabilities and limitations, as well as the necessary steps to create a larger project.

Some examples of mini projects in ECE include:

• Developing a basic circuit board with basic components such as resistors, capacitors, and LEDs.

• Creating a simple programmable logic controller (PLC) to control an automated system.

• Designing a small robotic arm using servos and 3D-printed parts.

• Building a basic drone with a camera and remote controller.

• Designing an embedded system to control a system with sensors and actuators.

• Developing a basic wireless communication system using RF transceivers.

• Creating a basic FPGA design to control a digital device.

• Building a simple embedded system for a medical device.

• Developing a basic computer vision system to detect objects.

By taking on mini projects in ECE, students can gain valuable experience and explore emerging technologies in a hands-on way. This type of project can help students gain insight into the technology, as well as the necessary steps to create a larger project. Furthermore, these mini-projects can allow students to gain confidence in their ability to work with new technology and provide invaluable experience in the field of ECE.

0 notes

Text

BELT TESTING MACHINE WITH MESSUNG'S NX-ERA XPRESS PLC SERIES

0 notes

Text

MESSUNG AUTOMATION SOLUTIONS FOR THE PLASTICS INDUSTRY

Automation is now an essential part of industry; the key to being competitive in a globalised market. The plastic industry is no exception.

As an industry looking to improve productivity, reduce operating costs and create innovative products, the plastic industry relies increasingly on automation. Advances in control systems have helped to reduce the human content in the manufacturing process, enhancing accuracy, speed and quality, especially in repetitive tasks.

Messung's connections with India's plastic industry goes back three decades. Based in Pune, Messung develops customised automation and control solutions for different machines and processes in plastic manufacturing. With more advanced diagnostics, controls, and tremendous growth in software sophistication, Messung’s industrial automation and control can help manufacturers rise to the challenge of constantly-growing demands for lower cost and optimisation.

HOW AUTOMATION CAN BENEFIT PLASTICS MANUFACTURING

- Allows manufacturers to boost throughput, control quality, improve time to market

- Enables production of smaller, more complex parts

- Allows companies to produce lower volume quantities of seldom-ordered products

- Automated visual inspection helps ensure consistent batches of products that are defect-free and standard-compliant

- Reduces the number of human-related rejections and errors; reduces risk of contamination from human workers

- Reduces risks of serious injury where operators are working in dangerous environments or moving components that require special handling

MESSUNG SOLUTIONS FOR THE PLASTICS INDUSTRY

Messung offers a wide range of automation solutions to help you make your plastics business more efficient. Whatever the process - injection moulding, machining, parts handling, palletising - Messung can help optimise your value chain. Messung's solutions also react flexibly to new developments, thus providing a future-proof system.

With rich experience in implementing and scaling up manufacturing automation solutions, Messung offers control solutions for most plastics manufacturing processes, such as:

Plastic Injection Moulding Machine: Manufacturers demand consistency, repeatability and accuracy from their injection moulding. Messung's automation solution sets consistent parameters which are monitored and controlled by the machine, thereby ensuring improved parts quality. The same high-quality results are achieved every time, and you also benefit from improved uptime and cycle times.

Plastic Extrusion Machine: Whether you are extruding plastic for a screwdriver handle or moulding, Messung can provide a state-of-the-art extrusion control system that enables better accuracy and consistency throughout the high-volume manufacturing process.

Messung's expertise can also integrate complex extrusion systems with multiple lines. Using a combination of standard features with optional process monitors, you can monitor each machine from the extruder to the end of the downstream. Alarms and user-friendly controls will facilitate troubleshooting thereby ensuring optimal performance at all times.

Plastic Blow Moulding Machine: Messung's solution offers temperature and Variable Frequency Drive control, to fulfil most standard blow moulding machine requirements. The functions are easy for operators to modify. Messung also offers service to hydraulic blow moulding machine owners/makers who are looking to upgrade their systems.

Roto moulding machine: Automation and temperature control are crucial in modern rotational moulding machinery. Messung develops customised solutions for both new machines and retrofitting applications. From automating the mould opening and closing, and the dosing system to the temperature controller which monitors internal temperature of the mould through the entire production cycle, and many more features - Messung's industrial automation solutions keep your moulding operations running smoothly, efficiently and sustainably.

Thermoforming Machine: Thermoforming is a process of heating a thermoplastic sheet to its softening point.The sheet is stretched across a single-sided mould and manipulated. Then it cools into the desired shape.

Messung can provide automation solutions at various stages like Sheet Feeding, Heating (PID controllers), Press Control & Product Thickness Control. Due to Automation, the process and materials can be optimised for cost effectiveness.

CONCLUSION

It should be noted that automation is rarely 'plug and play', and plastics manufacturers need a vendor who can deliver a complete system that meets and exceeds their production requirements. Messung partners with plastics companies to deliver the most relevant solutions. Utilising more user-friendly controllers, software and touch-screens, Messung's control systems are designed to be more accessible to the average operator and facilitate smooth, reliable operations.

Messung is the leading PLC manufacturer in India, offering a complete range of advanced PLCs and control systems incorporating motion control systems,VFDs, servo drive products, HMIs and more.

Besides the large Nx-era Premium Programmable Logic Controller to the Nx-era Xpress mini PLC, and servo & motion control solutions from its partners, Sigmatek, Austria and Fuji Electric, Japan, Messung also offers advanced remote I/O modules developed indigenously at their own Technology Centre in Pune.

For retrofits or new machines in your Plastics industry, call Messung. Pioneer of India's first indigenous PLC, Messung had decades of experience and knowhow to provide customised, cost-effective automation and control solutions to boost productivity, reduce operating costs while helping you meet your industry's sustainability goals.

Messung not only provides IoT-enabled automation and control for the entire range of requirements - from single machine to linked plant, they optimise every process stage and ensure greater reliability.

#automation and control solutions#industrial automation and control#PLC manufacturer in India#motion control systems#VFDs#servo drive#Programmable Logic Controller#mini PLC#servo & motion control solutions#remote I/O modules#PLC

0 notes

Link

There are a host of possibilities in the marketplace when it gets to automation. It can be an emotionally charged argument over which brand rules the world, primarily when the discussion centers around the PLC and PAC. Fortunately, there are a lot of right products out there, but one product we tend to overlook is the smart relay, mini-PLC, programmable relay, or similar.

0 notes

Text

GIC PC10ED16003N Programmable Logic Controller PLC is used to monitor inputs, and depending upon their states, it makes decisions based on its program or logic so as to control (turn ON/OFF) its outputs to automate a machine or a process. Programmable Logic Controller PC10ED16003N can control a wide variety of devices to support User’s automation needs. The Programmable Logic Controller monitors inputs and changes outputs as controlled by the user program, which can include Boolean logic, counting, timing, complex math operations and communications with other intelligent devices. The compact design, flexible configuration and powerful instruction sets are combined to make the Programmable Logic Controller a perfect solution for controlling a wide variety of applications. Now you can seamlessly implement automation in your electromechanical processes with GIC’s Programmable Logic controller PC10ED16003N. It is a real-time system designed for multiple input and output arrangements and has applications in both, Industrial and Commercial sectors. PLC application has a sturdy framework with unique functional characteristics such as sequential access control, ease of programming, timers and counters, easy-to-use hardware, and consistently secure controlling capabilities. The PLC applications and uses of Programmable Logic Controller’s are broad and diverse. Be it a residential, commercial, or industrial setting. Take your manufacturing processes to the next level with GIC’s smart relay & Mini PLC’s, specially designed to offer greater control in even the harshest and most hostile conditions.

1 note

·

View note

Text

STUXNET - O Primeiro tiro da Ciberguerra

Se você ler muito sobre Malwares, ou o mínimo, já deve ter ouvido falar do Stuxnet, o malware que deu início a um novo cenário de guerra que ninguem até então se importava. O stuxnet foi um worm[1] governamental altamente sofisticado e silencioso criado pela suposta parceria EUA-Israel para atrasar o enriquecimento de urânio do Teerã. O motivo é que o urânio é o elemento essêncial para a criação de armas nucleares, ou seja, o objetivo era atrasar o desenvolvimento nuclear do país, o que funcionou, já que mil centrífugas de urânio foram danificadas, atrasando o enriquecimento mais ou menos em 2 anos. O stuxnet não foi apenas um malware qualquer criado por qualquer hacker de 20 anos, foi uma arma digital governamental extremamente sofisticado que precisaria de muito investimento. O malware foi o primeiro tiro que representou o início de um novo cenário de guerra: A CiberGuerra/CyberWar.

Se futuramente a ciberguerra tomar proporções gigantescas, com toda certeza vamos lembrar do stuxnet como o ponto zero desse novo tipo de guerra. Já penso que legal estudar o Stuxnet nos livros de História?

OBS: Esse post foi escrito em uma madrugada de 4 horas, que por coincidência, é o tempo de duranção média da cafeína no sistema nervoso. Erros de português, como tempo verbal ou falta de coesão, serão comuns ao longo dessa jornada, perdoe-me.

[1] Worm é um malware que tem a habilidade de se espalhar sozinho. [2] Agência Internacional de Energia Atômica [3] https://www.correiobraziliense.com.br/app/noticia/mundo/2010/11/28/interna_mundo,225248/wikileaks-rei-da-arabia-saudita-pediu-aos-eua-ataque-militar-ao-ira.shtml [4] https://oglobo.globo.com/mundo/israel-admite-ter-atacado-suposto-reator-nuclear-na-siria-em-2007-22510494 [5] Zero day é o termo técnico usado para vulnerabilidades que ainda não possuem correções, e portanto, continuam funcionando.

# Da política até os códigos

Bom, tudo tem uma política por trás, com o stuxnet não foi diferente. Então vamos a um resumo dos acontecimentos.

A história começa bem lá atras, em 1968, com a criação do Tratado de Não Proliferação de armas nucleares (TNP), o tratado visava a limitar o desenvolvimento nuclear das grandes potências nucleares, sendo elas Estados Unidos, Rússia, Reino Unido, França e China. O acordo permitiu que esses grandes paises pudessem permanecer com os poderes que já possuiam e proibiu o compartilhamento de armamento ou informações de tecnologias nucleares com países que não possuiam tal tecnologia. Mas o acordo não começou bem por conta da desigualdade nuclear dos signatários, quando as grandes potências assinaram o acordo eles já possuiam um poder bélico nuclear muito avançado, e os paises que não tiveram tempo de desenvolver nenhuma dessas armas ficaram incomodados com as restrições e o monopólio bélico das grandes potências. Por esse motivo muitos países, inclusive o Brasil, discordaram e tiveram muitas diplomacias até os países concordarem e ratificarem o tratado.

Porém o tratado continuou gerando problemas por conta da dificuldade da AIEA[2] de fiscalizar e garantir que os países signatários estão cumprindo com os acordos, inclusive as grandes potências, que prometeram diminuir o seu arsenal. Mas o grande causador de problemas até hoje é o irã; que já causou, e causa, diversos alvoroços por conta do seu programa nuclear iraniano, que alega ter apenas intuitos tecnologicos pacíficos.

Em 2003, e meio a tanta confusão, o irã assina a adesão ao protocolo adicional do tratado TNP e concorda em suspender o enriquencimento de urânio, e todo mundo fica mais calmo, especialmente o Ocidente que diz não confiar o irã com armamento nuclear. Em 2006 o irã fica puto, mete o foda-se pra todo mundo e inicia pesquisas nucleares com alegação de que é para fins civís (kkkk) e ainda diz que limitará as visitas da fiscalização, nada suspeito huehueirã. O resumo é que desde de 2003 o irã descumpriu 4 acordos preocupando os Estados Unidos, Israel e os países do Ocidente, que não ficaram nada contentes. O incomodo fez com que muitos paises, entre eles Estados Unidos e Israel, apoiassem e incitassem alguma forma ofensiva de impedir o avanço nuclear do irã. Em dos documentos vazados pelo Wikileaks, o rei da Arábia Saudita pediu ao EUA que atacasse o irã por conta do seus avanços nucleares[3] e o presidente egípcio, príncipe herdeiro de Abu Dhabi e outros também apoiavam o ataque. Basicamente geral tava puto pedindo ajuda para o papai EUA pra descer o cacete no moleque teimoso do irã.

Apesar da insistencia de Israel para apoiar um ataque aéreo nas instalações do irã, George Bush, o presidente do Estado Unidos na época, estava contra por medo da população achar que o EUA estavam apenas procurando pretexto para atacar o irã. Não era a primeira vez que Israel pedia apoio para bombardear instalações, em 2007 os agentes da inteligencia de israel invadiram o quarto de hotel de um importante funcionário sírio e simplesmente plantaram um malware no notebook dele, através do malware descobriram que os sírios estavam montando um reator nuclear para construir armas com ajuda da Coreia do Norte. Com isso eles ganharam suporte do EUA para atacar o reator nuclear da síria, o ataque foi nomeado de Operação Pomar[4].

-- Aprendizado de hoje: nunca deixe seu notebook sozinho em nenhum lugar e criptografe seu HD, aproveitando vá ler meu post sobre criptografia com luks e veracrypt ;) --

Israel agora queria fazer o mesmo com as instalações do irã, porém, o cenário não era tão simples como na síria, o ataque era muito mais complexo em questões técnicas e sociais, e possivelmente causaria diversos problemas até mesmo econômicos; por essas e outras razões o ataque aéreo estava fora de cogitação para G.Bush, o presidente do EUA. Depois muitas opções de ataques não muito boas eles chegaram a uma ideia genial: Um ataque digital. Essa opção era a melhor que eles tinham conseguido, pois seria os mesmos resultados e com poucas consequencias e riscos. A operação foi chamada de Jogos Olímpicos(OG, Olimpic Games) e mais tarde nomeada de stuxnet pela mídia e empresas de segurança.

O plano era um malware altamente sofisticado, inteligente e independente, ele se espalharia por outros computadores e saberia identificar o seu alvo, agiria de forma silenciosa mas que desse resultado significativos. O plano não era destruir totalmente, e sim atrasar os avanços nucleares do Irã até que as situações diplomáticas sejam resolvida de alguma forma, plantando um malware na principal instalação em Natanz.

Sem barulho, sem mortes, sem digitais, e capaz de penetrar em qualquer instalação e com poucos riscos, uma arma digital silenciosa, era o plano perfeito.

Isso me lembra aquela frase do wallpaper do kali: "more quieter you become more you able hear"

Se você quiser saber mais detalhadamente sobre a história por trás do Stuxnet eu recomendo o livro Contagem Regressiva ao Zero Day, o livro no qual o post está sendo baseado. Também recomendo o documentário ZeroDay.

# Uma monstro à solta

A primeira versão do Stuxnet foi então instalada fisicamente através de agentes duplos de Israel que tinham acesso a Natanz, já que a mesma era isolada da internet exterrna, e por isso passava um sentimento de segurança. Inicialmente o malware não era tão agressivo, na verdade era bem mais simples e precisava de uma execução manual para funcionar, mas a ambição de agressividade de Israel fez com que o malware recebesse atualizações e fosse ficando cada vez mais forte, agressivo e inteligente, até demais. O malware foi contando cada vez mais com zerodays[5] e funções que o permitiam ser mais eficaz no seu propósito, o plano seria perfeito se não fosse por israel.

Israel não estava satisfeito, sempre incitando a NSA à deixar o malware mais e mais agressivo, eles não percebiam o que eles estavam criando e nem nas consequências disso. O malware foi então sendo desenvolvido até chegar em um ponto onde eles não tinham mais controle, o stuxnet, que deveria ser uma operação precisa e secreta, começou a criar vida própria e se espalhar pelo mundo inteiro sem controle, até eles perceberem a merda que fez quando o malware chegou nas instalações da Rússia e caiu nas mãos do Serviço de Segurança Federal da Rússia (FSB). O malware começou também infectar o EUA, o que alertou as agências de segurança, mas como o projeto era ultra secreto só um pequeno grupo de pesssoas sabia sobre, então o EUA começou a se defender de um ataque feito pelo próprio governo.

Mas Israel novamente não satisfeito pegaram o código do malware, modificaram e sem o conhecimento da NSA executaram. O update causou algum bug no sistema que começou a desligar os computadores, fazendo as máquinas entrarem em loop de reinicialização, o que alertou os engenheiros e as empresas de antivírus.

# Identificando o alvo

PLC, Programmable Logic Controller é um hardware que tem como função controlar, gerenciar e monitorar equipamentos e máquinas indústriais que precisam de um controle mais rígido e monitorado. São geralmente usados em infraestruturas críticas como Usinas de energia, fábricas, redes de energia e qualquer ambiente industrial que precise de um controle e monitoramento maior. Esses mini computadores são controlados e monitorados por um software específico da produtora. Esses softwares são nomeados de SCADA (Sistema de supervisão e aquisição de dados).

Uma das grandes marcas responsáveis por criar esses hardwares e softwares SCADA é a Siemens.

Em 2009 o governo do irã publicou um total de 48 fotos mostrando o presidente Mohammed fazendo um tour pela usina de enriquecimento de urânio em Natanz. Olhando parcialmente você só percebe homens de jalecos brancos em lugares cheios de máquinas, mas em uma análise profunda é possível reconhecer softwares SCADA, o tipo e marca de hardware, equipamentos, etc.

Um dos cientistas atras do presidente foi assassinado pouco tempo depois da foto.

Em uma olhada mais detalhada na tela do software SCADA no computador, é possivel identificar que haviam seis grupos de centrífugas e em cada grupo havia 164 peças, o que "curiosamente", é o numero exato encontrado no payload de ataque do stuxnet. E com uma analisada mais profissional, é possivel identificar que o hardware/software usado é da empresa Siemens. Portanto, a instalação de Natanz estava usando PLCs Siemens para controlar e monitorar as centrífugas de enriquecimento de urânio.

# O ataque

O stuxnet ao infectar uma máquina procurava por uma configuração e software específicos, caso a máquina não tivesse essa configuração ele ficaria ali sem representar nenhum perigo. Caso sim, ele procurava por modelos de PLCs extremamente específicos que não conhecidentemente pertencia a Siemens. Ao reconhecer a infraestrutura e os PLCs, o stuxnet começava silenciosamente registrar as informações de monitramento das PLCs ligadas a centrífugas por 13 dias sem se mover.

Ao passar dos exatos dias então, o stuxnet começava a entrar em jogo. Ele acionava um PLC rootkit que alterava os códigos baixo níveis dos controladores PLCs para aumentar a velocidade da centrífuga em 80%, assim com um tempo nesta velocidade elas se destruiriam. Ao alterar o código o rootkit enviava as informações antigas, registradas durantes os 13 dias, ao software SCADA, enganando assim os engenheiros que monitoravam e os alarmes de segurança. Assim os operadores olhavam para a tela e viam que as centrífugas estavam girando a 1000hz, enquanto na verdade estavam se destruindo girando a 1800 hz. E quando os operadores tentassem apertar o botão vermelho de desligar tudo, o stuxnet interceptaria e ignorava o comando.

Mas acelerar as centrífugas à essa velocidade causa um barulho notável muito grande, o que uma hora ou outra alguem desconfiaria. Então o stuxnet foi atualizado para tentar outro tipo de ataque, de vez acelerar as centrífigas causando aquele barulho ele iria fazer o inverso, ele iria desacelerar as centrífugas a 2hz, isso causaria uma oscilação fazendo elas quebrarem.

- O stuxnet foi o primeiro malware a mostrar um Rootkit para PLC, que até então nunca tinha sido visto antes em qualquer lugar.

# Arquitetura o stuxnet contava com diversos tipos de vulnerabilidades e técnicas que tornava possivel a sua disseminação. Como por exemplo:

- Propagação por pednrives. Ele fazia uma cópia de si para pendrives usando um zeroday que permitia se auto executar quando o pendrive infectado fosse conectado. [BID 41732] http://www.securityfocus.com/bid/41732 - Propagação através de vulnerabilidades zerodays SMB. [MS08-067] http://www.securityfocus.com/bid/31874 - Propagação através de zerodays no serviço de impressão Windows Print Spooler. [MS10-061] http://www.securityfocus.com/bid/43073 - Propagação através de computadores com WinCC databse server. - Escalação de privilegio através de vulnerabilidades [MS10-073]. https://docs.microsoft.com/pt-br/security-updates/securitybulletins/2010/ms10-073 - Controlava o sistema operacional através de um drive assinado windows rootkit nomeado de "mRxnet.sys". - Assinava o drive do rootkit mRxnet.sys com certificado roubado da Realtek, assim o sistema tinha confiança no drive.

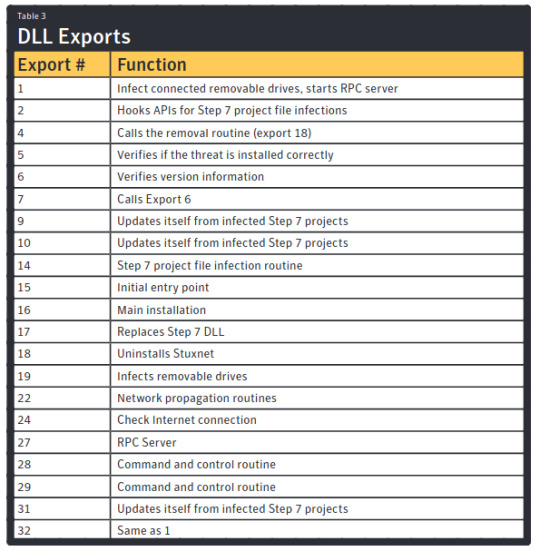

# .DLL Grande parte das funções vitais do stuxnet se localizava em um arquivo criptografado .dll, é a tabela de funções e recursos que o malware exportava para executar as atividades e instalações no sistema. É onde fica todo o sistema de controle do malware.

- DLL(Dynamic-link library) é uma biblioteca dinâmica composta por uma tabela de funções que serão carregadas para algum programa quando chamadas. Abaixo uma imagem de todas funções dll.

Em vez da tabela dll ser carregada no disco, ela era injetada em um outro processso em execução através de técnicas avançadas de Process Injection, assim mantendo o DLL na nuvem (RAM). O stux escolhia o seu processo alvo que seria injetado com base nos softwares de segurança instalados, alguns eram processos pré-definidos, como processos de antivírus:

Kaspersky KAV (avp.exe) Mcafee (Mcshield.exe) AntiVir (avguard.exe) BitDefender (bdagent.exe) Etrust (UmxCfg.exe) F-Secure (fsdfwd.exe) Symantec (rtvscan.exe) Symantec Common Client (ccSvcHst.exe) Eset NOD32 (ekrn.exe) Trend Pc-Cillin (tmpproxy.exe)

Outros processos padrões do windows que poderiam ser usado

Lsass.exe Winlogon.exe Svchost.exe

Um desses acima poderia ser escolhido com base no AV.

# Privilégio Adminstrativo Após a dll ser carregada ele fazia algumas verificações como versão do windows, se o computador já está infectado, qual software de antivirus está instalado e se ele tinha ou não acesso de Adminstrador. Se caso ele detecte que não tem permissões de administrador, ele escolhe um zeroday baseado na versão do sistema operacional windows para Escalação de Privilégios. Em Windows XP ele explorava a falha MS10-073.

O stuxnet só executaria em uma dessas versões do windows: Win2K WinXP Windows 2003 Vista Windows Server 2008 Windows 7 Windows Server 2008 R2

Após a exploração ser bem sucedida ele criava um novo processo, dessa vez com permissões adminstrativas e injetava novamente o arquivo dll nesse processo.

# Instalação Depois das etapas anteriores bem sucedidas e acesso adminstrativo, o stuxnet então partia para a sua instalação principal que contava com a infectação diversos processos para a disseminação, inclusive o processo service.exe afim de poder infectar pendrives, e exportava alguns arquivos criptografados para o disco:

O arquivo de log - oem6C.PNF O arquivos de configuração - mdmcpq3.PNF Arquivo dll de funções principais do stuxnet - Oem7a.pnf

Nesta mesma etapa ele extrai também dois arquivos criptografados para o disco, ambos chamados de Mrxnet.sys e Mrxcls.sys. Esses eram os drives com rootkit que a após instalado ocultava alguns arquivos do stuxnet e mudava a data de criação deles para a mesma data de outros arquivos no sistema para evitar suspeitas, também fazia com o que o stux se iniciasse quando o windows fosse iniciado.

Abaixo uma imagem da rotina do stuxnet.

# Command and Control (C&C) Após todo a sua instalação e reconhecimento do sistema o stuxnet enviava informações sobre o sistema infectado para domínios disfarçados de sites de futebol.

www.mypremierfutbol.com www.todaysfutbol.com

Dessa forma a equipe que pesquisava sobre o malware conseguiu acessar o domínio e redirecionar os dados, permitindo o rastreio mundial de cada computador infectado pelo malware.

# O reconhecimento do erro

Apesar do stuxnet ser uma ciberarma altamente sofisticada pensada em um plano perfeito, o projeto não ocorreu como deveria. O malware que o EUA-Israel criou para atrasar o irã não foi tão eficaz, o que era pra ser um ataque silencioso, na verdade, foi extremamente barulhento. A suposta frase dita por Obama na sala de Situação quando foi avisado pelos Coroneis de que o malware havia vazado.

"Me disseram que os iraniano nunca descobririam do malware, eles descobriram. Me disseram que ninguem saberia que foi o EUA, agora sabem. Me disseram que isso teria um grande efeito no programa nuclear deles, e não teve."

O irã após a descoberta do stuxnet não demorou até revidarem:

Aramco, a maior companhia de petrolífera do mundo teve 35.000 computadores destruidos em questão de horas, a estrutura da companhia que oferece 10% do óleo mundial estava em risco. https://money.cnn.com/2015/08/05/technology/aramco-hack/ https://www.nytimes.com/2018/03/15/technology/saudi-arabia-hacks-cyberattacks.html

Ondas de ataque a vários bancos no EUA deixaram todos sem acesso as suas contas https://en.wikipedia.org/wiki/Operation_Ababil https://www.forbes.com/sites/thomasbrewster/2016/03/24/iran-hackers-charged-bank-ddos-attacks-banks/#42a8e0677255

Isso foi uma bela fudida mensagem do irã ao EUA dizendo: "Nós também podemos brincar". Não é atoa que hoje o irã tem uns dos maiores ciberexército do mundo.

e se aviões pudessem ser hackeados? ou hospitais e bancos sem sistemas, ou um pais com sua comunicação interrompida, desastres tecnológicos, a ciberguerra não é mais algo de filme cyberpunk, agora é real.

O Estados Unidos não apenas fracassou como também apresentou ao mundo um novo cenário de guerra perigoso, iniciou uma nova corrida armamentista, um novo tipo de exército. E isso não pode ser parado, talvez limitado, assim como armas nucleares e químicas foram limitadas, talvez em um longo futuro de desastres as cyberarmas sejam tão perigosas quanto uma bomba nuclear.

Be safe!

fontes: Zerodays Documentário sobre stuxnet https://www.amazon.com.br/Countdown-Zero-Day-Stuxnet-Digital/dp/0770436196 https://www.symantec.com/content/en/us/enterprise/media/security_response/whitepapers/w32_stuxnet_dossier.pdf

1 note

·

View note

Text

NX-ERA Xpress PLC - Small Footprint, Big Performance

NX-ERA Xpress is a powerful mini PLC (Programmable Logic Controller) developed by Messung, leading micro PLC manufacturer. NX-ERA Xpress brings you world-class technology at a cost-effective price - for entry-level applications.

0 notes

Text

New trends in Programmable Logic Controller

A programmable logic controller (PLC) is an automated system that collects data from a variety of input devices, including sensors that monitor parameters such as storage tank levels, pressure, and temperature. Using programmed software logic, the PLC then processes the collected data, makes appropriate logic-based decisions, and sends issued instructions and commands to process and machine control. PLCs have been around for nearly 50 years and are still considered the best option for a wide range of industrial automation applications. Despite that era, PLC technology is evolving and PLCs are expected to maintain their dominance in the world of industrial automation for the next few years. Below are some of the 10 latest technological developments that have evolved and adapted PLC technology to the times.

1) Compact size, faster processing time, cost optimization

Technical improvements such as reduced size of processor, circuit board and other components. It's changing the electronics industry. In addition, these improvements are beginning to affect PLCs after the introduction of small micro and nano-class PLCs. These new PLCs are smaller, but with faster cycle times, larger memory capacity, new communication improvements, and faster processors.Prior to , the above features were only high-end and mid-range PLC features, but in response to market demand, many of the high-end features have been moved to low-end PLC systems. As a result, we have moved from a large PLC to a small PLC. This is because micro and nano classifier PLCs can also provide remote connectivity, Ethernet communication, onboard PID with auto-tuning, motion control, and other control functions.For example, PLC manufacturers are taking advantage of the dramatic reduction in size and cost of solid-state memory. This allowed for a significant increase in local data storage, allowing PLCs to be used in many applications that initially required expensive data acquisition systems. In addition, the reduced memory size allows for many other features such as on-board storage of product information and faster debugging of PLC control systems.In addition, current PLCs benefit from USB technology, making online programming and monitoring of control systems much easier. In addition, as USB technology continues to evolve with the availability of micro and small mini USB connectors, these communication options are expected to be incorporated into smaller PLCs.In addition to USB readers, the PLC also integrates with SD cards, micro SD and mini SD cards, and other small connected devices. These portable devices provide PLCs with up to 32GB of additional non-volatile storage, depending on the needs of system integrators, machine builders, or end users. This is a hallmark of the fast-paced consumer electronics industry, where integration with PLC is rapidly revolutionizing industrial control systems.

2) Enhanced Communication Networks

Over the past few decades, especially in the early 1990s, a wide variety of communication protocols and networks have been developed for use in industrial communications. This trend continues to focus on real-time communication technologies, raw Ethernet connection speeds, and other industrial control networks for a variety of applications. In their present form, high-end PLCs include multiple ports to support several communication protocols. But looking into the future, this is likely to change as users continue to demand more standardized Ethernet and Wireless communication options. Even though it’s a wireless age, industrial processes would require more robust wireless technologies with enhanced data integrity and improved communication range, before we can witness a convergence of industrial and commercial wireless communication protocols.Though there has been great progress in this field, from the latest ZigBee (802.15.4) and Wi-Fi (802.11n) protocols to the use of mesh and wireless ad hoc networks (WANET) as well as the rise of Near Field Communication (NFC) and Industrial Bluetooth; none of these wireless technologies has proven capabilities for mission-critical operations often encountered plant floors. Therefore, in the future, a great deal of less critical PLC controlled applications in which real-time control isn’t essential, are likely to widely adopt wireless communication networks particularly in RTUs (remote terminal units).

3) PAC (Programmable Automation Controller) and PLC Integration

In general, Programmable Automation Controllers (PACs) are an enhanced modular industry that uses PC-based processors to provide even more programming. It is a controller for. Option IEC61131-3 programming language. Also called an industrial PC or just IPCPACs are considered more advanced than PLCs. However, over the years, PLCs have evolved to adapt to improvements in hardware technology, software, and communications. High-end features are built into the low-end PLC processor.For example, with larger memory capacity and faster processors, we have the opportunity to integrate advanced features with PLCs such as: B. Motion control, simultaneous support for multiple communication protocols and high resolution image processing systems. On the other hand, despite its advanced features, the PAC system maintains the simplicity of appealing SPS to many end users. In addition, the capabilities of PAC allow users to push the boundaries of traditional industrial automation and product designers to create custom controllers to suit their needs.Throughout this evolution, many industrial control manufacturers have continued to promote the difference between PAC and PLC. However, at the same time in PLC and PAC, the definitions and characteristics of both classes changed, and much faster progress was seen in both classes. Therefore, as the two controllers evolve, the two functions will continue to be integrated. In fact, in the future, automation engineers may move away from nomenclature and focus on the features and performance available when specifying control systems.

4) Open Source PLC

When you come across the term "open source", you think of an open source hardware design, or a standardized, non-exclusive PLC scripting language implemented under a public license. However, the impact of the open source era on the PLC industry is very comprehensive.PLC technology completely eliminates the concept of PLC by suggesting that it should be based on a computer system such as the Raspberry Pi. More and more companies are adopting Raspberry Pi and incorporating it into systems that are robust and can withstand the extreme environments of industrial applications. In this case, the Raspberry Pi is typically paired with one or more boards that provide the digital / analog and I / O capabilities that make up a traditional PLC.With Raspberry Pi, the additional circuit boards are designed with the capability to withstand high currents and voltages and to provide the isolation required in an industrial environment. Therefore, in terms of hardware, the Raspberry Pi can at least be integrated into industrial automation through such extensions.In terms of software, single-board computers such as Raspberry Pi are not designed to be programmed with IEC 61131-3 standard languages like Function Block Diagram or Ladder Logic used to program PLCs. Instead, Raspberry Pi runs on an operating system like Linux or a derivative of Linux, and such an O/S is best accessed by high-level programming languages including Java, C and C++, and other higher levels of abstraction which purely use mathematical expressions. This is quite different from the bit-bashing environment of Microcontrollers Units (MCUs), that support Ladder Diagram and other IEC languages.However, some companies like Phoenix Contact are taking advantage of the open-source disruptions in the PLC market, to create open programming platforms like “PLCnext”. "PLCnext" is an open programming environment based on Linux O / S, but intended for PLC applications. This is achieved by using high-level IT technologies such as HTML or by giving system designers the option to configure the control system based on the IEC 61131-3 programming language.

5) PLCs Design designed for Industry 4.0 Many technological innovations such as artificial intelligence, cloud computing, advanced sensors, and big data analytics are having a major impact on the manufacturing situation. These advances in industrial technology are commonly referred to as Industry 4.0. In the reality of this new industry, PLCs continue to play an important role as main controllers, input hubs, and interfaces for human operators.To continue to be the central processing unit for real-time manufacturing operations, PLC technology has been further developed to enable better communication with multiple input sensors over the Industrial Internet of Things (IIoT). This makes it much easier for SPS to capture large amounts of data and deliver it to machine learning programs.For example, data from input sensors and other devices can be integrated with PLC data to give a “big picture” of the collection of “big data”.Operations managers and data analysts use analytics tools to better track big data, leverage resources, perform logistics, plan orders, plan tasks such as timing suppliers. , You can create a very efficient manufacturing process. In addition, "big data" can be tracked and analyzed for optimal performance and preventative maintenance of machines and appliances in manufacturing systems.

6) Integrated programming environment

We tend to combine human-machine interface (HMI), motion control, and PLC into an integrated programming environment. This trend may continue for the next few years. This is followed by integrating the PLC with the HMI processor on the same rack and including the monitor as part of an external option or package. This technology allows the configuration of either HMI modules or HMI processors with PLC I / O racks.A non-overwhelming integrated programming environment is ideal for most system designers and control engineers. The main benefits of combining these modules include an overall reduction in program development time and a reduction in the learning curve. However, to get the most out of such tools, you need to think properly to make them easier to navigate.

7) More powerful and broader data exchange The PLC is more powerful and can be equipped with features previously reserved exclusively for workstations and PCs. This makes exchanging data from the PLC on the factory floor to a human operator in the control plane faster and cheaper. Features that allow current SPS to share data widely include internal relational databases, FTP servers, web servers, and sending email. Theweb server allows a PLC to host a website, for example, on the Internet or on the corporate intranet. The web server then provides access to real-time data logging and acts as a backup HMI for your work cell or machine.In addition, the web server feature can store documents on some PLCs, allowing you to view machine schematics and drawings, as well as operation and maintenance manuals with short video clips. As a result, PLC web capabilities vary from model and manufacturer design specifications, from a single "off-the-shelf" web page to a full-fledged site that uses JAVA and XML-based technologies. PLC web servers are probably the most popular of PLC's new data sharing technologies.In addition to the PLC web server, there is a Send-Email feature that simplifies and automates the export of critical and production data from the PLC to human operators. This allows the PLC control program to output production data, status changes, material consumption reports, alarms, and PLC internal data. Interestingly, the PLC's email sending feature allows you to quickly send alarm messages to maintenance personnel via your mobile phone or alphanum pager.

8) Advances in Ladder Logic

50 years ago, Ladder Diagram (LD) replaced hardwired relay logic as a PLC programming language. The LD language kept things simple for system engineers and designers accustomed to passing logic, but at the time there were some limitations, especially when it came to data processing and process control.Other PLC programming languages such as function block diagrams (FBD), structured texts (STX), sequential function charts (SFC), and instruction lists (IL) are introduced in IEC61131 to address the challenges of ladder diagrams. It was-3.3. However, the developers of ladder diagrams have responded to that advance. This surprisingly remains relevant and powerful in industrial control programming. All IEC languages have advantages because STX is suitable for data manipulation. However, ladder logic is still on the rise and continues to be the overwhelming leader in PLC programming languages.For example, control system vendors and end users support large-scale base installations of devices, machines, and processes controlled by ladder logic PLCs. There is also a large group of maintenance personnel, electricians, technicians, and engineers who prefer the simplicity of ladder logic programming technology. In addition, regardless of the hardware used, the LD language has come a long way in creating industry standards for PLC programming. This trend may continue for the next few years.

9) PLC Designs that Withstand Harsh Conditions

PLCs that are currently available in the market are rugged and designed to withstand extreme climatic events like cold snaps, floods, or heat waves; conditions that could potentially damage electronic devices including PLCs. These robust and sturdy PLCs designs are being made with more durable materials like fiber signals instead of electronic signals, making them well-suited for some electronically hostile plant floors. In addition, due to the advancements in IIoT technology (previously discussed), PLCs can now be housed in isolation of harsh environmental conditions and operated remotely from regions with less or zero electrical noise disruptions. This has proven to be of great benefit whenever there are sensitive processes and sensors which require precise actions and monitoring

.10) Higher Security

Cybersecurity is becoming increasingly essential with the rise of interconnected devices in this era of the Internet of Things. For instance, interfering with the visibility of sensor systems or shutting down sensors, could cause work sites and plants to shut down; resulting in enormous losses. To contain or prevent this from happening, industrial control manufacturers are responding by incorporating the latest safety enhancements into their PLCs. For example, Honeywell Process Solutions (HPS) released the Control edge programmable logic controller in 2016. This PLC has a built-in cyber security function to prevent cyber attacks. In addition, Honeywell's next-generation controller leverages the power of the Industrial Internet of Things (IIoT).

0 notes

Text

PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, a PLC Training Institute In Pune. Our institution leads the way, offering specialized courses and advanced centers dedicated to teaching PLCs. Whether you are starting your career or trying to hone your skills, our bespoke programs meet a variety of needs.

Firstly, Perfecto Robotics Institute offers hands-on training led by industry experts. Students actively participate in practical exercises. Students develop a deeper understanding of PLC systems by doing p; practical exercises. Additionally, our instructors emphasize real-world applications, ensuring graduates are well-prepared for technological challenges.

What is PLC?

It stands for Programmable Logic Controller. PLC is the ruggedized computer used in industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

Different types of PLC

Mini PLCs

Modular PLCs

Fixed PLCs

Micro PLCs

Nano PLCs

Safety PLCs

Types of PLC Output:

Analog Output

Relay Output

Triac Output

Transistor Output

PLC features:

Robustness

Flexibility

Modularity

High-speed Operation

Reliable I/O Handling

Networking Capabilities

Programming Languages

Diagnostic and Troubleshooting Tools

Data Handling and Storage

Scalability and Upgradability

Overall, these features make Programmable Logic Controllers indispensable tools in industrial automation.

In conclusion, Perfecto Robotics Institute is the best PLC Training Institute In Pune. We stand out for its practical approach, advanced facilities, and industry-related learning. Contact us to start a successful career in industrial automation.

Explore our courses today and take the first steps to becoming a professional PLC professional.

Looking for top-quality PLC training in Pune? Our institute offers hands-on training in PLC programming Learn from experienced trainers, gain practical knowledge with real-time projects, and boost your career prospects with our comprehensive courses. We offer flexible batch timings, affordable fees, and placement assistance to help you succeed. Enroll now and become job-ready in automation!

0 notes

Text

PLC Training Institute In Pune

What is PLC?

PLC stands for Programmable Logic Controller. PLC is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

Different types of PLC

Mini PLCs

Modular PLCs

Fixed PLCs

Micro PLCs

Nano PLCs

Safety PLCs

Types of PLC Output:

Analog Output

Relay Output

Triac Output

Transistor Output

PLC features:

Robustness

Flexibility

Modularity

High-speed Operation

Reliable I/O Handling

Networking Capabilities

Programming Languages

Diagnostic and Troubleshooting Tools

Data Handling and Storage

Scalability and Upgradability

Overall, these features make Programmable Logic Controllers indispensable tools in industrial automation.

In conclusion, Perfecto Robotics Institute is the best PLC Training Institute In Pune. We stand out for its practical approach, advanced facilities, and industry-related learning. Contact us to start a successful career in industrial automation.

Explore our courses today and take the first steps to becoming a professional PLC professional.

0 notes

Text

Projects For Electrical Engineering Students

In our lifestyle, Projects For Electrical Engineering are very useful in many fields, and that they need more power in comparison with other projects. The circuits of these projects were designed with passive components like resistors, capacitors, inductors, and many more. But many diploma and engineering students don’t know an idea about how they work and which projects may come under this category. For those students here we are providing some projects which will be helpful for their project work.

Many of the engineering graduates showing tons of interest during this stream. Electrical and Electronics Engineering involves designing, controlling, and maintaining electrical equipment. Some of the project areas of the electrical field are power generation, power grid equipment maintenance and handling, industrial control and robotics, power electronics, and energy systems.

Here we, takeoff projects are providing the best Electrical Engineering Projects for Final Year Engineering Students. These projects are potential topics to be utilized in the ultimate year of EE projects. The following projects include major also as mini projects for diploma and engineering students. These projects are innovative and new electrical projects to pick as their project topic in their final year of engineering.

1. GSM-based Substation Monitoring and Control System

This project aims to accumulate various substation parameters like current, voltage, temperature, power factor, etc., remotely via GSM communication. Thus, the remote operator can analyze these parameter values and take a corresponding control action. A user can remotely operate the substation equipment like circuit breakers, isolators, relays, buzzer alarms, and so on.

2. Zigbee Based Solar Powered Forest Fire Detection and Control System

The idea of implementing this project is to detect and prevent forest fire remotely by using Zigbee communication. The entire transmitter circuit is located in the forest with different sensors like smoke and fire detectors, which are powered by a solar panel system. The embedded circuitry within the transmitter circuit collects processes the info and sends the info to a foreign PC through the Zigbee communication module.

3. Android Based Electrical Appliance Control

This is a complicated way of controlling the house appliances from a standard manual switch pressing system. It uses an Android mobile with a user graphical interface application in it. The negative feedback circuit is attached to a variety of devices to be controlled through a relay mechanism with a Bluetooth communication module.

4. Photovoltaic solar energy Generation with Maximum point Tracking

This system considerably minimizes the number of panels required to get the electrical power in order that reduces the photovoltaic array system cost. As the sun isn't constant in one place, and by fixing the solar battery at one fixed place, maximum power generation isn't possible.

Therefore, this technique locates the maximum-power-generating point with the MPPT controller.

5. PLC and SCADA Based Traffic Control System

This smart control system uses Programmable Logic Controllers (PLC’s) and SCADA HMI for monitoring and controlling traffic signals. This system is sort of useful in high-traffic-density areas, toll gates, and other high-end parking areas.

0 notes

Text

BELT TESTING MACHINE WITH MESSUNG'S NX-ERA XPRESS PLC SERIES

The belt center distance measurement is standard practice to measure the center distance of the flat belt and V belt. The belts are tested at a particular load in LBF at this load; the objective of the system is to find out the exact center distance and belt override of the belts. Some constituents of the testing apparatus are:

⮚ Pulleys – to stretch the belt and insert it

⮚ Load Cell – to measure the load or belt tension

⮚ Transducer – to calculate the belt override

⮚ Servo system – to generate the desired load

⮚ Magnetic Linear Scale – to measure the distance

APPLICATIONS WHERE BELT TESTING MACHINE IS USED :

ENGINE MANUFACTURER INDUSTRY

This system is majorly used in the engine manufacturer industry. The belts are tested for their reliability and durability.

THE CUSTOMER:

Our customer specializes in the Manufacturing of Standard & Customized Measuring equipment. These equipments are designed as per Industry Standards. Integrated with the latest technologies, these equipments provide reliable & efficient testing operations.

THE SOLUTION:

Messung is among the best PLC automation companies in India. Our engineers studied the plant and its requirements and came up with a solution consisting of

● NX-ERA XPRESS XP325 PLC Controller

● 7 inch HMI Display Touch Screen

● Servo System (Fuji)

Programmable Logic Controllers (PLCs) have been used in various control systems in order to increase efficiency, reduce the initial investment and minimize the long-term maintenance costs.

The NX ERA EXPRESS based machine offers a cutting edge user experience (UX). The screen - a plc automation control panel - allows the user to set test parameters, view test values during and after the test, and record test memories for future references. It allows the user to have overall control over the entire test program with just a touch.

THE HEART OF THE SYSTEM: NX-ERA XPRESS

NX-ERA Xpress is a powerful mini PLC (Programmable Logic Controller) promoted by Messung - a leading micro PLC manufacturer. NX-ERA Xpress offers world-class technology at a cost-effective price for entry-level applications.

Loaded with advanced features, the NX-ERA Xpress micro PLC delivers high-speed processing power in a condensed design with embedded I/O. This micro PLC system can be easily expanded through the CANopen device using the Remote I/O Modules - a considerable advantage for OEMs with needs for small, scalable applications.

NX-ERA Xpress Highlights:

● High-density I/O both Digital & Analog

● Programming by Codesys® - IEC 61131 based software

● Ethernet Port - TCP/IP, Modbus TCP/IP

● Inbuilt Webserver

● Industry 4.0 ready - OPC-UA, MQTT features

● RS-485 port with Modbus RTU Master protocol

● CANopen Master/Slave protocol

● SCADA and HMI interfaces available

● Built-in HTML webserver

BENEFITS FOR THE CUSTOMER

The Latest Industry 4.0 enabled PLC System: Provides access to sensor-level data in difficult-to-reach areas. This helps ensure the smoother operation of system components while streamlining device replacement and machine maintenance – hence saving costs and enhancing efficiency.

Cloud connectivity

Conformal Coating: This coating ensures integrity even in harsh environments

Programming and configuration environment based on IEC 61131-3 standard: the global standard in plc programming for industrial automation.

Designed to meet the pertinent demands of Industry 4.0

THE OUTCOME:

⮚ With the help of automation technology, all systems are designed for unattended operation and automatic adjustment.

⮚ The controller brings unmatched performance which enhances the reliability of the system.

⮚ The feather-touch display screen works as an HMI for the setting of the Belt parameters in the form of recipe and test results are displayed on the screen and the report is generated in PDF format.

⮚ The report generation ensures the integrity of the test as no human error is encountered.

About Messung IA

Messung is amongst India’s leading industrial automation companies and offers cutting-edge customized solutions for factory automation, process automation and special purpose machine automation. Messung is considered to be one of the top 10 PLC manufacturers and offers an expansive range of world-class Programmable Logic Controllers (PLCs), Remote I/O modules, Servo & Motion Control solutions and Human Machine Interfaces (HMIs) for a variety of applications across a range of industries.

Messung also offers a varied range of Variable Frequency Drives (VFDs) and Servo/Motion products from Fuji Electric that are effective for simple to complex industrial applications.

For more information, visit: https://www.messungautomation.co.in

#PLC automation companies in India#mini PLC#Programmable Logic Controller#micro PLC#PLC system Remote I/O Modules#IEC 61131-3 standard#automation technology#industrial automation companies#factory automation#process automation#special purpose machine automation#top 10 PLC manufacturers#Programmable Logic Controllers#PLCs#Servo & Motion Control solutions#HMIs#VFDs

0 notes